IN-LINE TRIMMING COMPACT VACUUM PRESSURE FORMING MACHINECFP-6SP TYPE

Model with separate forming unit and trimming unit. Seamless process from forming to stacking, using compact and low-cost molds. Offers simplified mold change and compatibility with punching and Thomson blade trimming.

- Materials

- PP

- HIPS

- PVC

- A-PET etc.

Features

- New model developed to minimize mold costs by completing punching and stacking in the same process as forming for a wide variety of products in small lots.

- Punching utilizes male-female blades, and punching dies are compact with small feed direction, allowing ultra low-cost production.

- Forming molds are also compact and low-cost. Mold change operation is simple and setup change can be performed quickly, so even with frequent mold change, the machine’s utilization rate can be maximized.

- Thomson blade use is enabled by mounting a Thomson blade attachment to the press unit.

- Utilizes a medium-wave infrared radiator heater with high quick-response performance, which heats as far as the sheet interior.

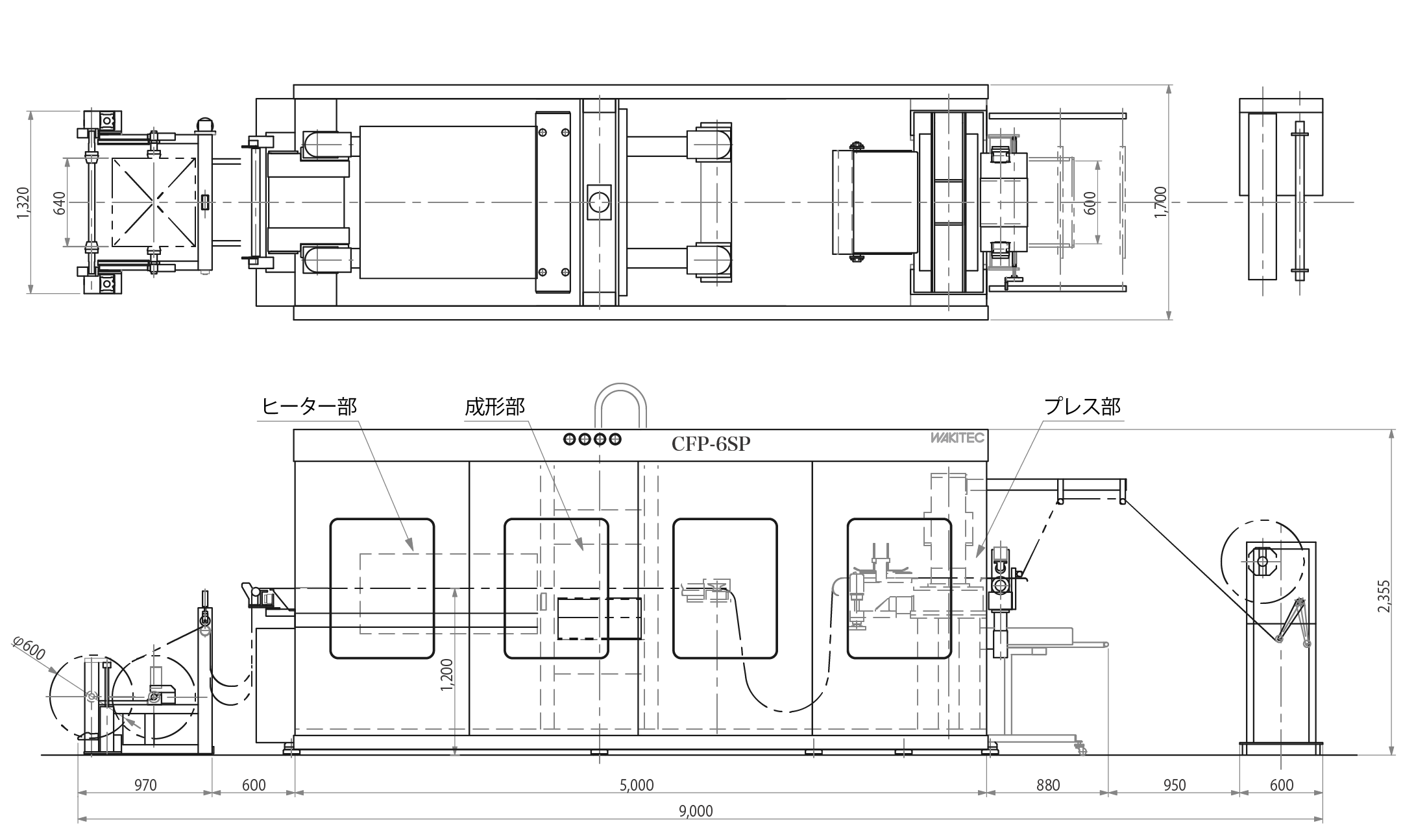

- Highly space-saving: the whole line, from raw film holder to finished product stacking conveyer, can be placed within a 9m length.

Reference Movie

Standard Specifications

CFP-6SP TYPE

| Raw film materials | PP, HIPS, PVC, A-PET, etc. |

|---|---|

| Forming method | Vacuum forming or vacuum pressure forming |

| Forming area | Maximum: 600mm (width) x 600mm (feed) |

| Minimum: 400mm (width) x 400mm (feed) | |

| Table vertical drive | Linear motion drive system via servomotor and ball screw |

| Forming pressure | 7,000kg.f |

| Heater | Medium-wave infrared radiator heater |

External Drawing

IN-LINE TRIMMING COMPACT VACUUM PRESSURE FORMING MACHINECFP-6SP TYPE