HOT PLATE COMPRESSED AIR FORMING MACHINEHPS-1100N TYPE

Optimized for OPS material sheets. Adopts novel method of temperature management during forming stoppages to minimize forming loss on restart. Significantly reduces setup change time.

- Materials

- OPS

- HIPS

- A-PET etc.

Features

Stable Hot Plate Temperature Management

- Uses a novel method of temperature management during pauses in forming, thus minimizing forming loss during restart.

Reduction of Setup Change Time

The following parameters are automatically set via data memorized and playback.

- Forming conditions

- Position settings of sheet presser, inlet guide, etc.

- Die shut height

- Compressed air pressure (Options)

- Area settings of compressed air hole (Options)

Space Saving

- Control panel/operating panel fully built into the machine body. Additionally, a large-volume compressed air pipe is modularized and built-in.

Improved Maintainability

- By widening the opening section of the machine’s sides, we have made the surface plate easy to clean and maintain.

- Features a remote (electrical) maintenance system. In the event of any electrical system trouble, we can provide solutions via online support.

Options

- Additional options available by request, including jib crane and camelback for puncher used in production line.

Main Specifications

HPS-1100N TYPE

| Raw Materials | OPS, HIPS, A-PET, etc. |

|---|---|

| Forming Method | Direct heated compressed air forming via hot plate |

| Forming Area | Minimum: 600㎜ (W) × 600㎜ (F) |

| Maximum: 1100㎜ (W) × 1200㎜ (F) | |

| Die Vertical Drive | Toggle drive system using servomotor and ball screw |

| Forming Pressure | 60 TON.f |

| Machine Weight | 9TON |

| Power Supply | 87kW(90kVA) |

| Operating Air | 3500ℓ/min (minimum of 5kg/㎠) |

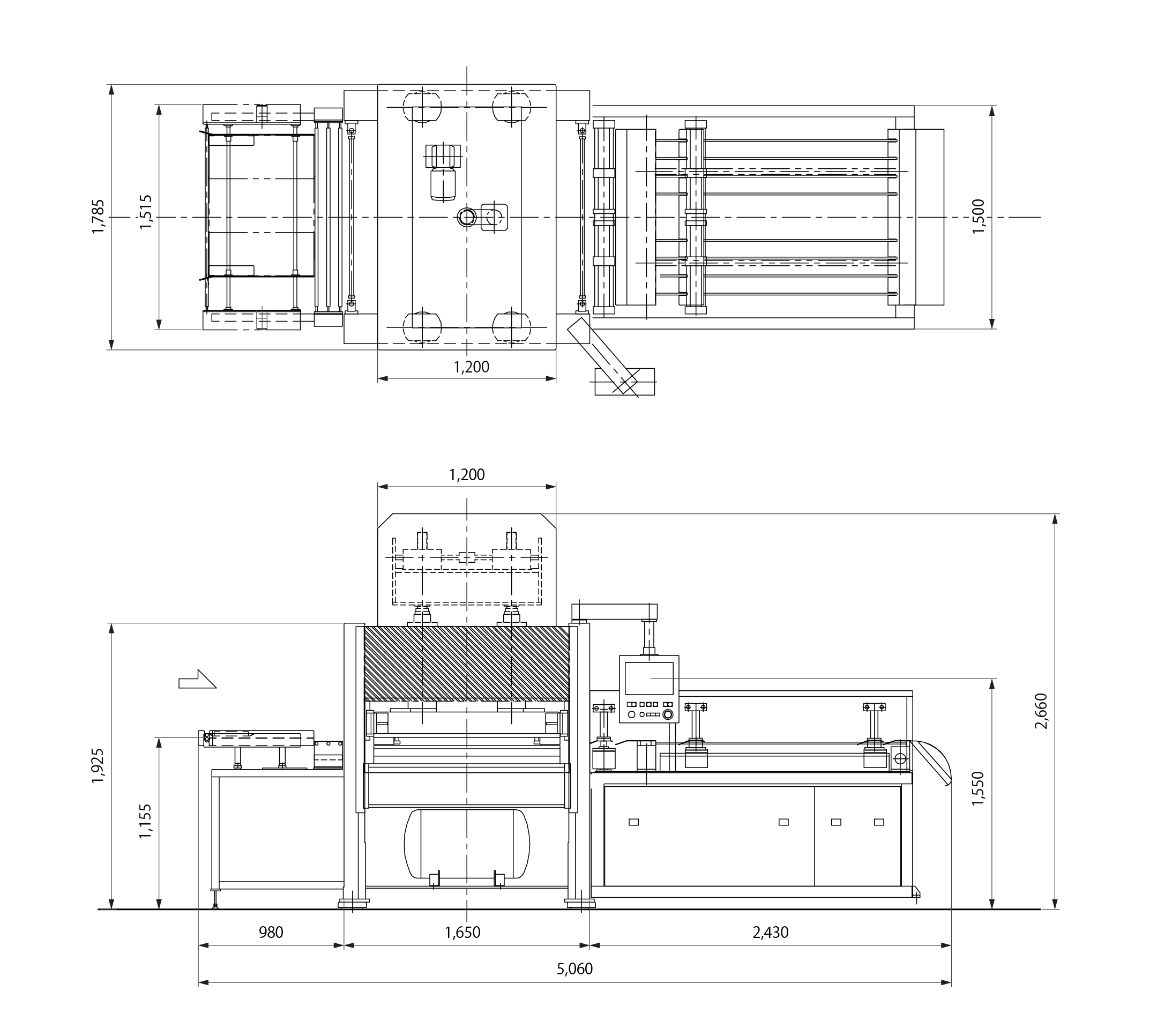

External Drawing

HOT PLATE COMPRESSED AIR FORMING MACHINEHPS-1100N TYPE