Forming tests can be used as a “lab” to evaluate sheet forming compatibility, for quality checking, or for sample manufacturing of new products. With forming tests, we support your product development process.

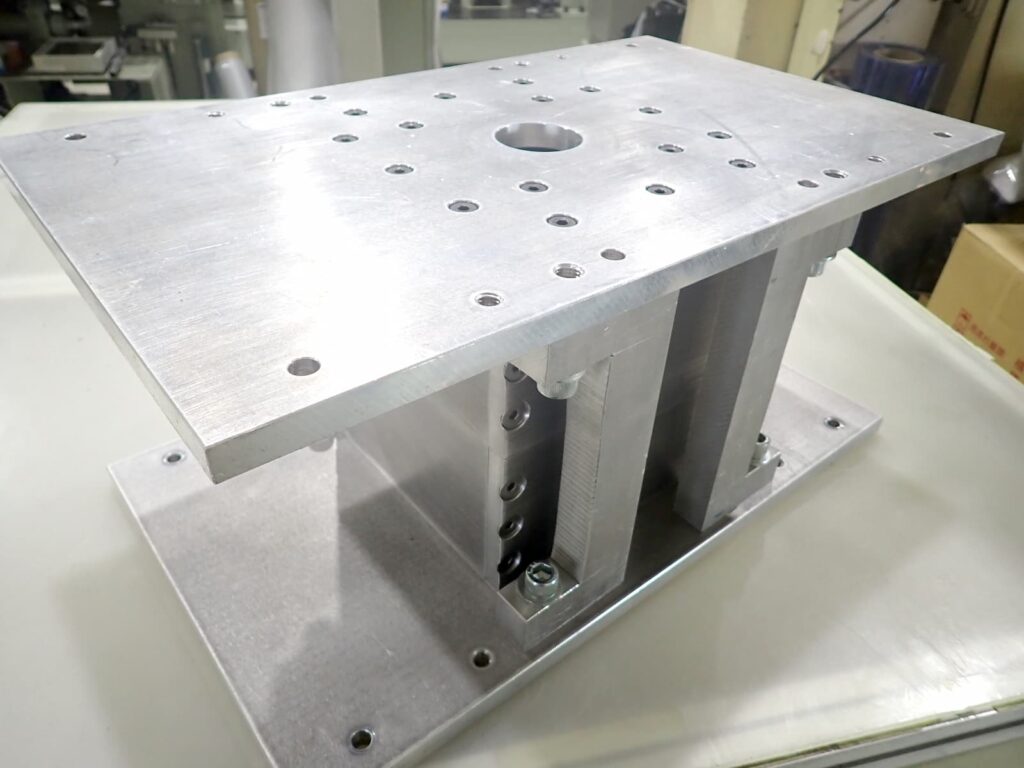

At WAKITEC, our test forming machine (FVS-500A) is permanently installed as a demo unit.

Our FVS-500A was originally developed to facilitate simple lab testing for materials (sheets) with unknown formability, which are difficult to process with full-scale production machinery. Test forming allows for the evaluation and reexamination of a material’s composition or formulation, as well as efficient assessment of whether it can be formed using mold shapes appropriate for the intended product.

Designed as a lab device, FVS-500A is now used by manufacturers across a wide range of industries. In addition to use by sheet manufacturers as a lab unit for assessing sheet forming compatibility, it is also used by mold manufacturers to verify design details and provide supporting evidence for proposals, and is utilized by forming manufacturers to facilitate opportunities for sample production and new product development testing.

Additionally, there are a growing number of use cases by forming manufacturers for the purpose of manufacturing small-lot product lines that not viable on full-scale production machinery.

About Forming Tests

In forming tests, parameters such as forming temperature, forming air pressure, sheet heating time, mold vertical movement speed, and the timing of mold and vacuum operation can be set in 0.01-second increments. Our engineers can also attend the test to provide technical advice and support.

Temperature, pressure, and other data obtained during testing can be copied to USB memory or similar storage. In addition, clients can keep the forming samples, and are generally permitted to take photo or video footage of the machinery or forming process.

We offer the initial test free of charge. Please feel free to contact us for more information.

Guide to Test Forming Machines

TEST-USE ULTRA-COMPACT VACUUM PRESSURE FORMING MACHINE FVS-500A TYPE

Ultra-compact vacuum pressure forming machine developed specifically for test forming. Allows high-speed forming and memory recall of forming conditions. Operates using (individual) cut sheets.

ULTRA-COMPACT HOT PLATE FORMING MACHINE HPT-400S TYPE

Hot plate forming machine for test use. When using OPS materials, we recommend HPT-400S. As with FVS-500A, forming is performed using (individual) cut sheets.

Notes for Forming Test Users

- As a general rule, please bring your own sheet materials.

*If you are unable to bring sheets, please contact us in advance.

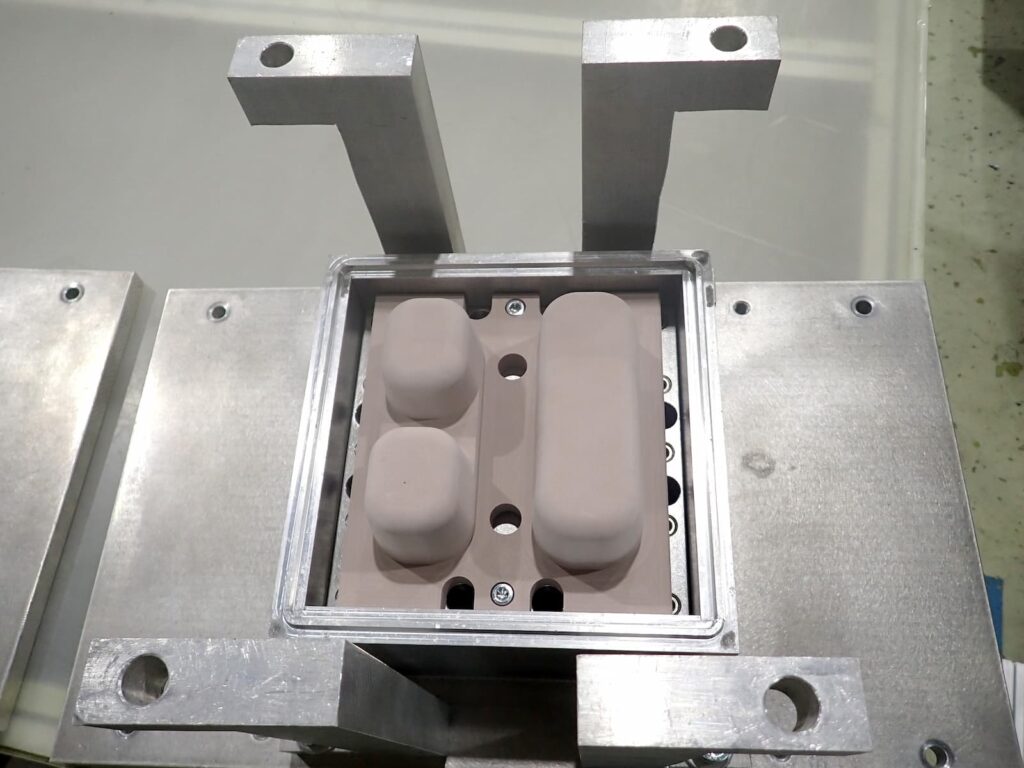

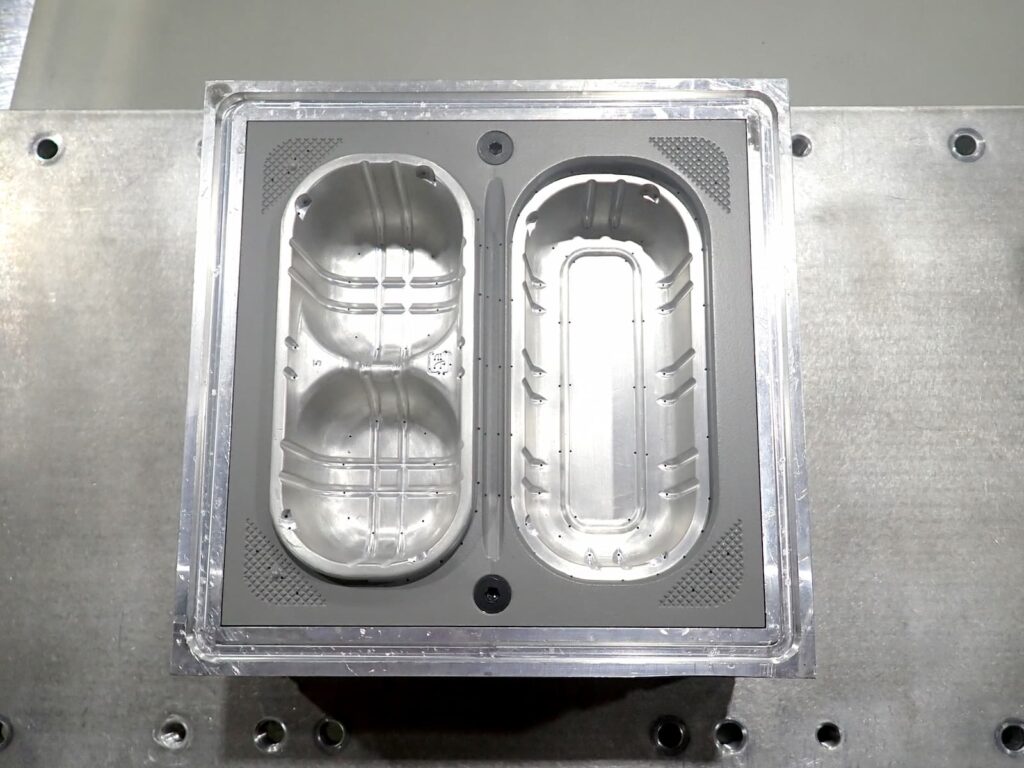

- WAKITEC’s in-house test molds are available for use.

*However, if you wish to test a specific product shape, we recommend bringing your own mold. (Please consult with us about mold mounting specifications.) We can also introduce you to mold manufacturers on request.

Forming Test Q&A

- Yes. Sheets of standard width (640 to 1000mm) can be cut with scissors for use, and general plastics (PP, PS, A-PET, etc.) of 0.1 to 5.0mm thickness can be used. However, perforated sheets (sheets with holes that allow airflow) may not be suitable, as vacuum pressure may not be effective.

- Mold dimensions vary from machine to machine. For example, if using WAKITEC’s FVS-500A, the maximum forming area is 500mm x 500mm, so molds must be within that size. There are no specific restrictions on mold weight. Regarding structure, any mold compatible with vacuum (or vacuum pressure) forming machines is generally usable.

- The most time-consuming step is usually mold setup, so it is difficult to give an exact time. However, the heater will reach the set temperature in approximately 15 minutes, and testing can begin immediately afterwards.

- Yes, there is no specific limit on the number of tests.

Contact Us

Please use the contact form to let us know about the type of products you want to test, and your desired testing schedule.