Product Catalogs

Introducing WAKITEC's Products for Energy Optimization & Labor-Saving

Search by Purpose

Search by Product

Auxiliary Equipment & Other

ROUND BLADE TRAVELING ONE-SHOT CUTTING SHEAR MACHINE

WKS-1000 TYPERound blade traveling method achieves high-safety shearing. Features include removal of cutting dust and automatic posi…

DOUBLE WINDING SHAFT-TYPE SCRAP WINDER

WSD-800, 1000 TYPEScrap winder equipped with two scrap winding shafts. When one shaft reaches maximum winding volume, winding can be rest…

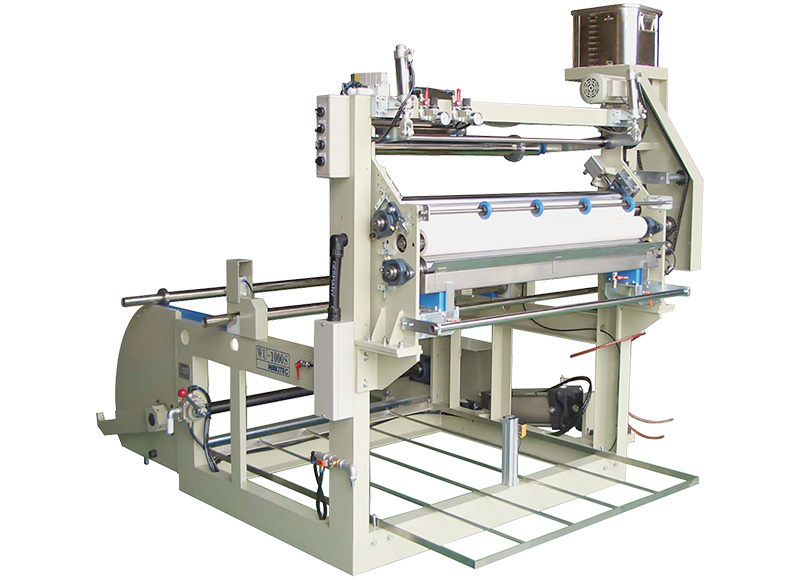

TRANSFER-TYPE SILICON COATING MACHINE

WU-800S, 1000S TYPERaw film feed machine capable of applying silicon coating. Silicon liquid is applied evenly using plated and rubber rol…

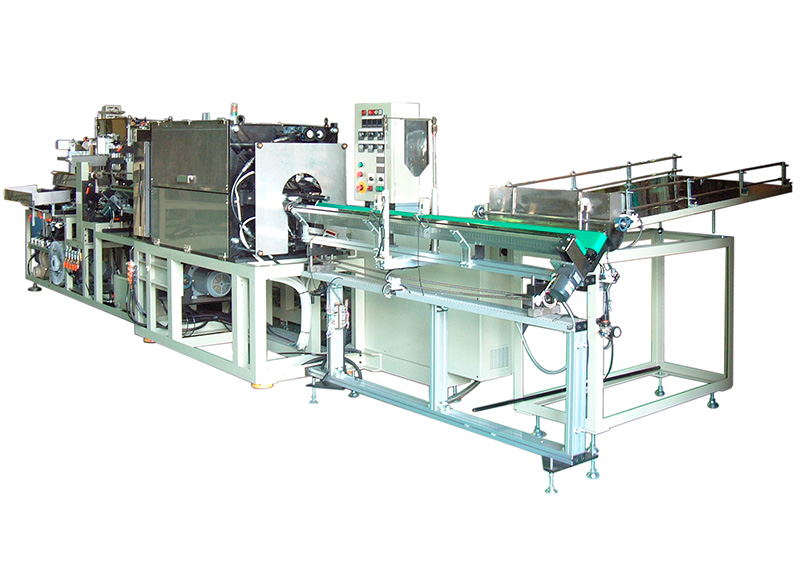

CURLING DEVICE

CRP-120 TYPEEnables curling, counting, dust removal, and packing on a continuous production line. Curling can be easily adjusted to…

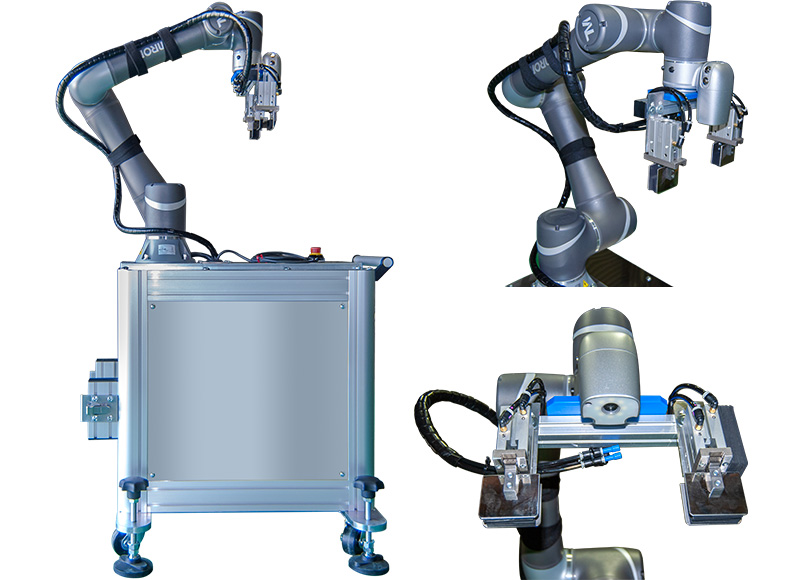

COLLABORATIVE ROBOT AUTOMATIC BOX PACKING DEVICE

KDR-1 TYPECollaborative robot facilitates automation of boxing process, which until now has required human labor. Unitization of …

Manufacturing Process

MEETING

Through in-depth meetings with customers at the initial stage, WAKITEC listens to details of the desired product's specifications, purpose and installation environment as well as specific requests. We use this information to propose optimal solutions.

DESIGN

Based on the contents of the meetings, we carry out design work with consideration for all aspects of the machine, including structure, functions, and safety, and create suitable drawings and 3D models.

PARTS MANUFACTURING

Using the design drawings as a basis, we precisely manufacture each part needed for the machine, either in-house or at a partner factory. We take all possible measures to ensure quality control.

ASSEMBLY

The manufactured parts are carefully assembled by WAKITEC's skilled staff on our in-house assembly line. We then finalize the configuration of the machine, including electrical components and piping.

ELECTRICAL WIRING

& DEBUG

We perform the necessary electrical wiring work, and debug the software.

TEST RUN & INSPECTION

We perform fine-tuning and test runs of the machine's operation in-house, meticulously checking the performance, operating accuracy, and safety of each component. We immediately correct any malfunctions or areas needing adjustment.

WITNESS TEST

We carry out a witness test with the customer, checking the exterior and operation of the finished machine together.

SHIPPING

After the witness test is completed and inspection is passed, the machine is packed in protective materials and shipped safely to the customer. Our packaging is designed with consideration for the conditions during on-site delivery and installation.

INSTALLATION

& TEST RUN

After installing the machine at the customer's factory, we perform an on-site test run. We verify and adjust the machine's functionality, and provide operational training and support for the start of full-scale operation.