Product Catalogs

Introducing WAKITEC's Products for Energy Optimization & Labor-Saving

Search by Purpose

Search by Product

Vacuum & Vacuum Pressure Forming Machines

VACUUM PRESSURE FORMING MACHINE

FP-835, 1045 TYPEForming table drive system uses toggle arm method for high-speed forming. Setup time is minimized with the memory recal…

VACUUM MICRO-PRESSURE FORMING MACHINE

FSP-800A, 1000A TYPEVarious data can be input and displayed via the LCD touch panel. Forming table drive uses linear motion drive system vi…

Download PDF

VACUUM FORMING MACHINE

WFS-800, 1000 TYPEWAKITEC's standard vacuum forming machine, this model prioritizes advanced energy-saving and thermal efficiency. Centra…

Download PDF

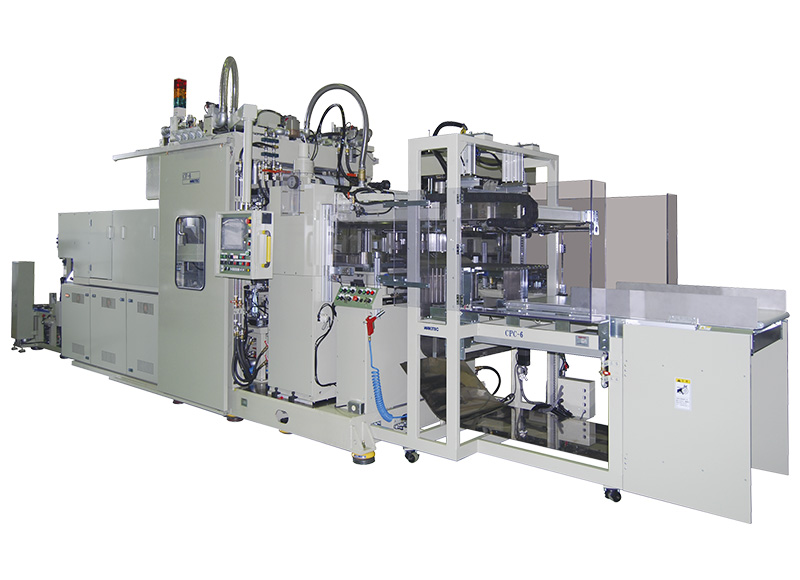

IN-LINE TRIMMING COMPACT VACUUM PRESSURE FORMING MACHINE

CFP-6SP TYPEModel with separate forming unit and trimming unit. Seamless process from forming to stacking, using compact and low-co…

IN-LINE TRIMMING COMPACT VACUUM PRESSURE FORMING MACHINE

CFP-6T TYPEModel with integrated forming and trimming unit. Compatible with Thomson blade trimming only. Completes punching and st…

TEST-USE ULTRA-COMPACT VACUUM PRESSURE FORMING MACHINE

FVS-500A TYPEUltra-compact vacuum pressure forming machine developed specifically for test forming. Allows high-speed forming and me…

Download PDFManufacturing Process

MEETING

Through in-depth meetings with customers at the initial stage, WAKITEC listens to details of the desired product's specifications, purpose and installation environment as well as specific requests. We use this information to propose optimal solutions.

DESIGN

Based on the contents of the meetings, we carry out design work with consideration for all aspects of the machine, including structure, functions, and safety, and create suitable drawings and 3D models.

PARTS MANUFACTURING

Using the design drawings as a basis, we precisely manufacture each part needed for the machine, either in-house or at a partner factory. We take all possible measures to ensure quality control.

ASSEMBLY

The manufactured parts are carefully assembled by WAKITEC's skilled staff on our in-house assembly line. We then finalize the configuration of the machine, including electrical components and piping.

ELECTRICAL WIRING

& DEBUG

We perform the necessary electrical wiring work, and debug the software.

TEST RUN & INSPECTION

We perform fine-tuning and test runs of the machine's operation in-house, meticulously checking the performance, operating accuracy, and safety of each component. We immediately correct any malfunctions or areas needing adjustment.

WITNESS TEST

We carry out a witness test with the customer, checking the exterior and operation of the finished machine together.

SHIPPING

After the witness test is completed and inspection is passed, the machine is packed in protective materials and shipped safely to the customer. Our packaging is designed with consideration for the conditions during on-site delivery and installation.

INSTALLATION

& TEST RUN

After installing the machine at the customer's factory, we perform an on-site test run. We verify and adjust the machine's functionality, and provide operational training and support for the start of full-scale operation.